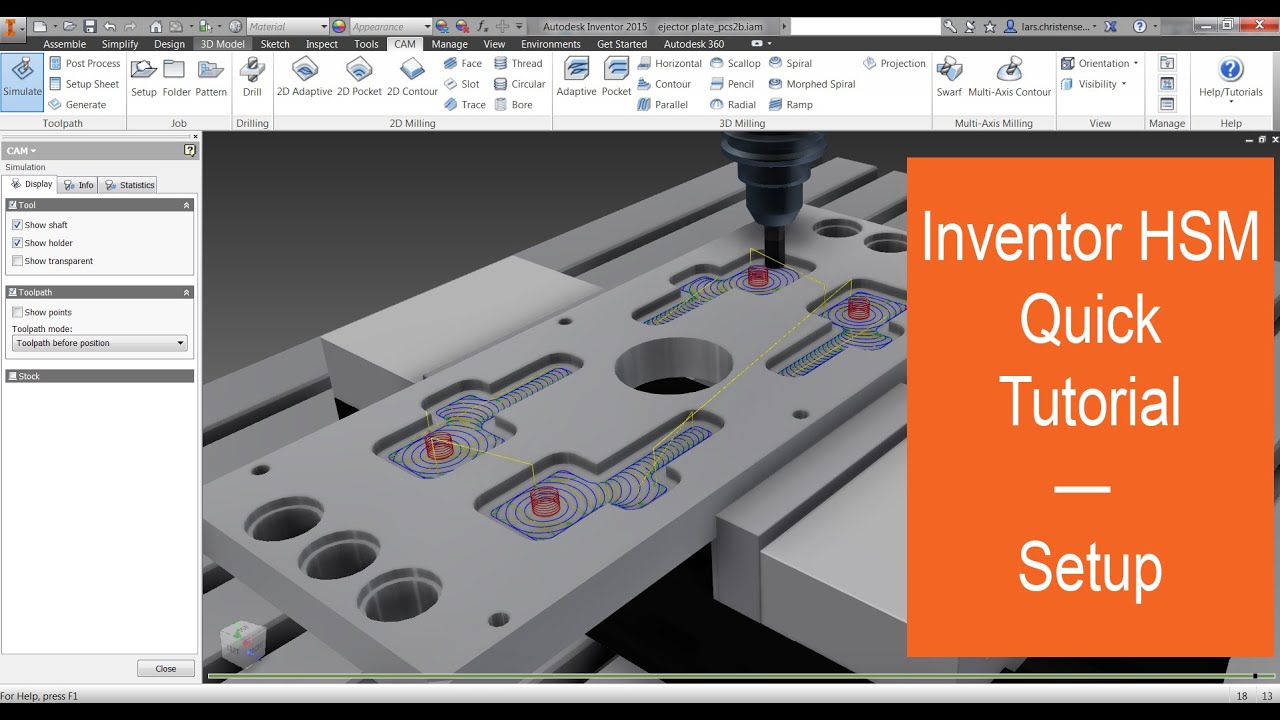

However, short line moves, coupled with high feedrates, may result in a phenomenon known as data starving.ĭata starving occurs when the control becomes so overwhelmed with data that it cannot keep up. Inventor CAM calculates very quickly and most modern controls have at least 1MB of RAM. The first two are not much of a problem because It is tempting to always use very tight tolerances, but there are trade-offs including longer toolpath calculation times, large G-code files, and very short line moves. More lines result in a toolpath that more closely approximates the nominal shape of the spline or surface. How accurately the toolpath matches the desired shape depends largely on the number of lines used. To accommodate this, CAM approximates spline and surface toolpaths by linearizing them creating many short line segments to approximate the desired shape. Model box point - Select a point on the model bounding box for the triad origin.ĬNC machine contouring motion is controlled using line G1 and arc G2 G3 commands.Stock box point - Select a point on the stock bounding box for the triad origin.

Setup WCS origin - Uses the workpiece coordinate system (WCS) origin of the current setup for the tool origin.

Origin drop-down menu offers the following options for locating the triad origin: Use this if your model does not contain a suitable point & plane for your operation. This uses both the origin and orientation of the existing coordinate system.

0 kommentar(er)

0 kommentar(er)